Cable assemblies are a cornerstone in the electronics and connectivity industries, and prototyping these assemblies facilitates the development and fine-tuning of new products. At Technical Cable Applications, we offer prototyping services that cater specifically to the diverse needs of various sectors. Our prototype cable assemblies act as preliminary models that help assess functionality, design integrity, and feasibility before reaching the production stage. With a foundation established in 2002 in Auburn, WA, our company has grown to serve clients across the United States and internationally, underscoring our commitment to innovation and quality.

The Process of Prototyping Cable Assemblies

The journey from concept to a robust prototype cable assembly involves several critical steps that we execute with precision and expertise. Our comprehensive prototyping services, available at our facilities in Washington State, Mexico, and Asia, ensure that our clients receive the highest quality cables and cable assemblies, tailored to their specific requirements.

Key Steps in Prototyping:

Requirement Specification: Our team meticulously defines the exact needs of the cable assembly, considering electrical, mechanical, and environmental factors.

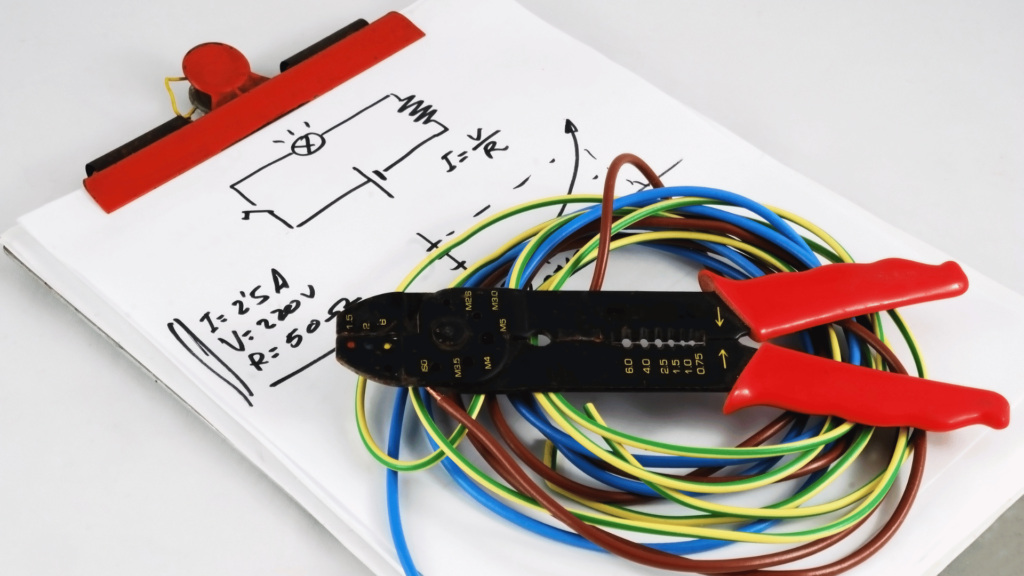

Material Selection: We carefully choose cable materials that ensure durability, flexibility, and optimal conductivity, aligning with the unique demands of each project.

Assembly and Testing: Using state-of-the-art equipment, we assemble the prototype and perform any crimping, thinning or other processes needed to replicate the planned cable assembly, and conduct rigorous testing to verify performance and reliability.

Iteration: We make necessary adjustments based on testing feedback to refine and enhance the assembly’s design and functionality.

Custom Cable Assemblies for Diverse Applications

We specialize in producing custom cables and cable assemblies that serve a wide array of industries, from telecommunications to automotive and medical technology. Our expertise in crafting custom solutions is supported by our commitment to reducing customer inventory costs through competitive inventory services and leveraging economies of scale, even in smaller production runs.

By focusing on custom cable assemblies, we ensure that each product is tailor-made to meet specific customer requirements, enhancing compatibility and performance across various systems and applications.

Quality and Reliability in Cable Assemblies

At Technical Cable Applications, our commitment to quality and reliability is unwavering. Every prototype cable assembly we produce undergoes stringent quality control measures to meet the high standards our clients expect. This dedication to excellence is mirrored in our continual investment in advanced technologies and tools, which streamline our manufacturing processes and improve product output.

Our manufacturing capabilities extend to wire harness production, injection molding, and OEM cable assembly, making us a versatile partner for businesses seeking robust and reliable cable solutions.

The Importance of Prototyping in Cable Assembly Manufacturing

In the fast-paced world of electronics, prototyping plays a crucial role in ensuring that new products are both functional and reliable before reaching the market. Prototyping cable assemblies is integral to this process, offering a practical way to test and refine designs.

Our expertise and state-of-the-art facilities allow us to provide prototyping services that meet the highest industry standards. Our ability to prototype, test, and manufacture within a single facility ensures a seamless transition from concept to final product, enhancing efficiency and reducing time-to-market.

Conclusion

As a leader in the field of prototyping wire harnesses and cable assemblies, Technical Cable Applications is committed to delivering top-quality products and services. Our dedication to innovation, quality, and customer satisfaction positions us as a trusted partner in the cable assembly and wire harness manufacturing sectors. Whether you require a straightforward custom cable assembly or a complex prototype, we are equipped to meet your needs with precision and excellence.

Contact us today to explore how our prototyping services can bring your project to life with unparalleled quality and reliability.