A first article and the corresponding first article inspection report are formal quality manufacturing practices that verify that a manufacturer has a complete understanding of their customer’s requirements.

A first article should be a single assembly meant to represent the gold standard of manufacturing the part in question. Production may include wide tolerances for manufacturing, but the first article should be the contract manufacturer’s opportunity to nail the spec.

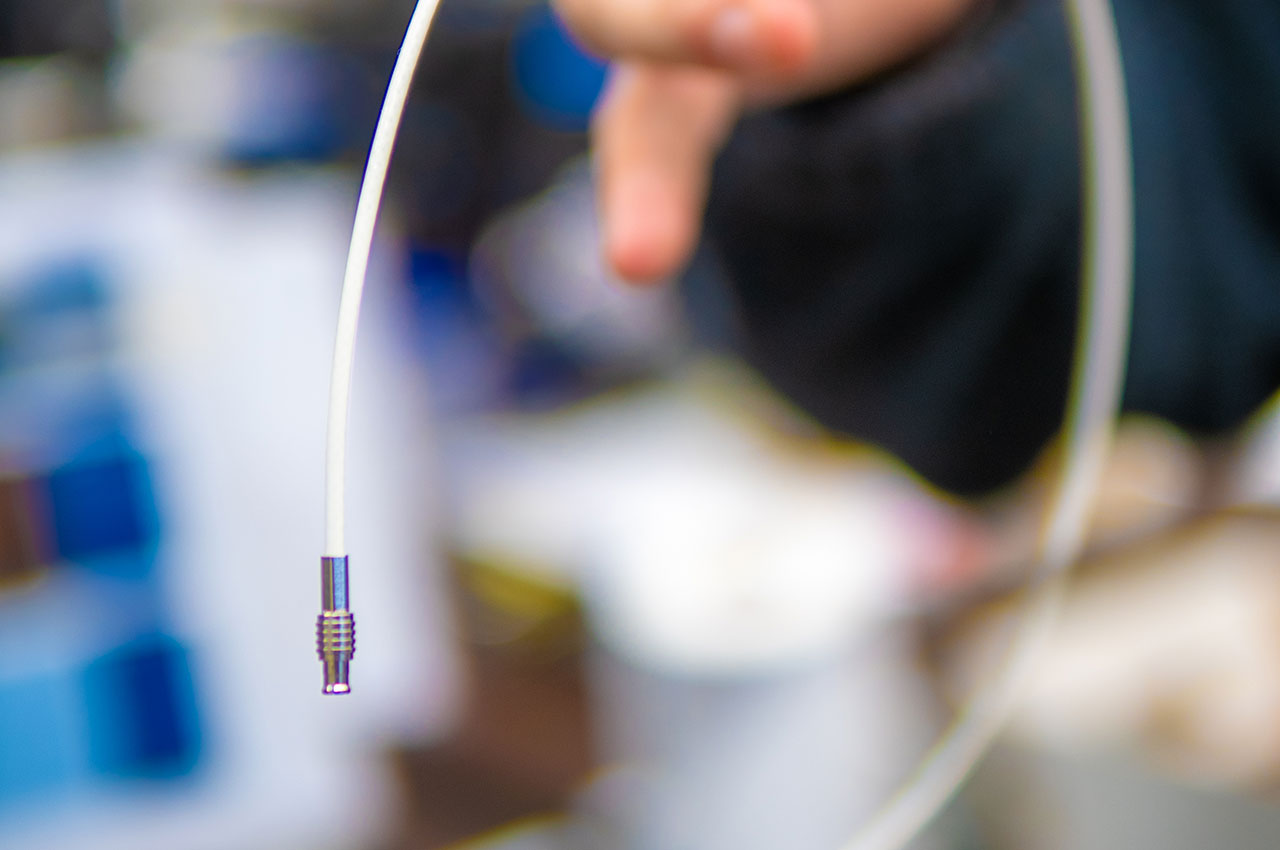

All inspection points on the drawing should be noted. For cables that should be all measurable dimensions, a complete continuity verification, labeling check, and a check of all special notes. That is in addition to the quality of the crimps, solder points, and other terminations, and other standard quality checks like the absence of debris and damage.

The first article report should go over each of these things and show the customer how their contracted manufacturer is interpreting the customer’s specifications. They should both make the part correctly, and understand why it is correct.

In addition to verification for the customer, the first article is the manufacturer’s opportunity to document the build. At TCA that includes documenting things like the wire cut lengths, strip lengths, tool settings, photos of the assembly, and generating label files, assembly instructions, and work instructions.

The first article is vitally important to the quality of ongoing production. TCA has a new product introduction team that is responsible for doing these documentation. Our quality team does the inspections and generates the inspection report. Our production mix is such that we are constantly doing new first articles, and onboarding new products is a specialty of ours.