Technical Cable Applications is your optimal choice for Ethernet, Cat-6, and custom fiber optic cables or cable assemblies that are highly customized to fit your product, server house, automated warehouse, or telecommunications hub and its unique needs. We are extremely knowledgeable and experienced with all forms of fiber data transfer cables and connectors as well including M12, coaxial, and all its variants such as Micro and RF, FAKRA, ribbon cables, and more. This means that no matter the application your fiber optic cable assemblies will be serving, and the complexity of their configurations, we can assemble hundreds or thousands of them with exacting precision after helping customize them down to the very last connector to fit your needs and specifications. We have been in business since 2002 and are fully UL certified for cable assembly in the United States and Canada, along with being ISO 9001:2015 certified for international standards as well. We also are ITAR certified for the United States in regards to defense contracting, showcasing our versatility and extremely high manufacturing quality for fiber optic cables, patch panels and much more. When you compare our qualifications to smaller custom cable manufacturers, we are at the top of our field providing highly customized cable assemblies like we always have at the best quality possible, but in bulk quantities smaller companies can’t match.

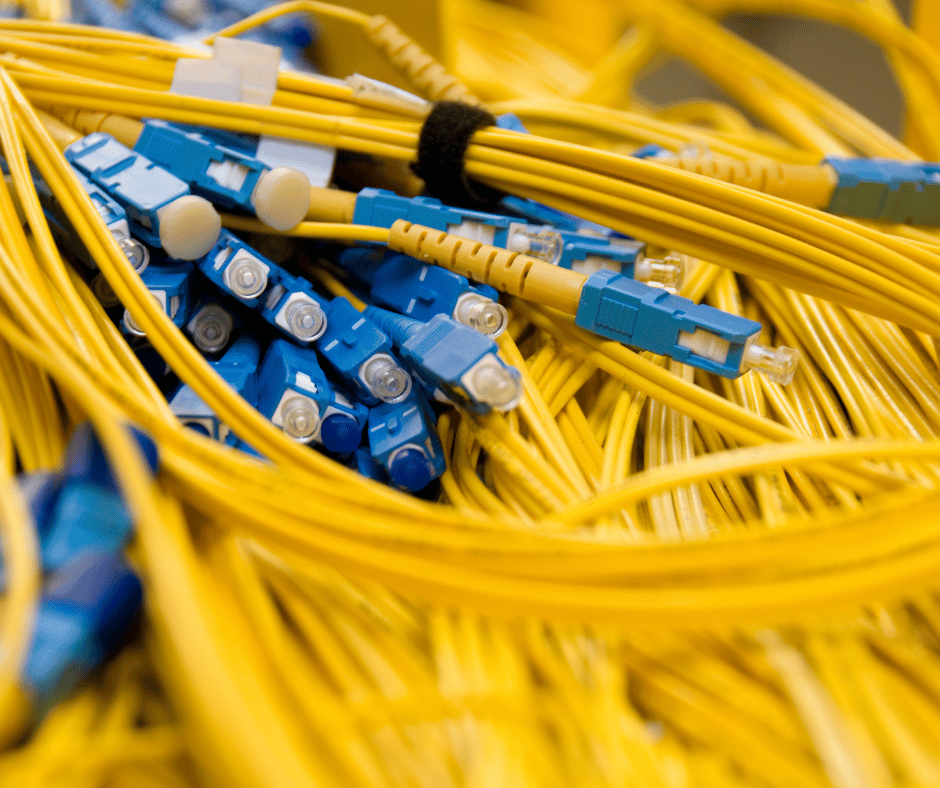

Custom Fiber Cables – Shielded Fiber Optic Cable Assemblies

If your need for fiber optical cables and patch sections includes them being in any sort of environmentally hazardous conditions, or even just encountering minimal but persistent damage over time from repeated contact, adjustment, etc., you need to ensure that your custom cable configuration is carefully shielded with not just any material, but specifically ones that will protect your fiber optic assemblies from harsh environments and prevent packet loss or full data interruptions. The actual fiber optic cables themselves must be made with durable materials as well in these cases. Our team are experts in the areas of molding, crimping, assembly and tinning for custom cable production, along with having in-depth knowledge about the ideal materials to use for all sorts of scenarios. For instance, one cable assembly material we often use for situations where temperature can vary widely i.e. outdoor applications is the polyamide known as Macromelt OM 946, which has a hardness rating of 92A and can continue operating safely in temps as low as -40 degrees Celsius and as high as 100 degrees Celsius which covers both extremes very easily. This is excellent for protecting not only fiber assemblies but all sorts of other connectors and applications, and we have many more materials we’ll use depending on your need.

Our custom fiber optics cable and patch solutions enable you to reach higher performance standards with incredible reliability and implement the cables into your products or facility right away. Rather than ordering OEM or off-the-shelf fiber optic cables with no customization and having to adapt them on the fly to your project, or trying to manufacture custom cables and patch panels in-house without the right equipment, ordering custom fiber optic and Cat-6 cables produced by Technical Cable Applications will be far more efficient and provide the best performance possible. We’ll take care of all the customization, patch needs, material and part sourcing and shielding requirements. We also work with nearshore manufacturing facilities who help us provide extremely fast lead times and lower our MOQ requirements, which can be very beneficial for highly customized cable assemblies, patch panels and configurations. You can benefit directly from our partnerships with these facilities by partnering with us at Technical Cable Applications for your custom cable needs today!

Need specialized fiber optic cables and patch systems for harsh environments or tight spaces? We are able to provide ruggedized and armored fiber optic cable assemblies for situations where standard cables and patch panels will be too fragile, or use bend-insensitive fibers to help ensure that your fiber optic cable assembly and any patch panels will be highly compact and fit within the small space you need. We can also take care of finer fiber optic details and ensure your fiber optic assembly meets even extremely strict requirements for bandwidth, attenuation, dispersion and signal integrity as all of these factors are extremely important for many industries, and must be precisely to specifications when testing to stay in compliance.

Fiber Cable With Custom Connector – Fiber Optic Cable Solutions

If you require bulk custom fiber optic cable solutions for your manufacturing or cloud computing needs, please contact us today with your cable drawing and specifications so we can get started! We’d be happy to take a look right away and get to work on providing a quote for you. Our team will provide you with an exact quote and expected lead times, and consult with you about any questions related to your fiber cables. We keep a strong inventory of all sorts of connectors and materials in-house so that we can begin prototyping and testing quickly for your custom solution. Fill out our online contact form or contact us at [email protected], and make sure to attach your cable drawing and any other details about quantity, materials and timeline.